-

1

Yolanda Wu

Phone: +86-17826810295

Landline: +86-0573-80886076

E-mail: [email protected]

-

2

Jane Shen

Phone: +86-13567361131

Landline: +86-0573-80886076

E-mail: [email protected]

-

3

Vivian Wu

Phone: +86-18358323481

Landline: +86-0573-80886076

E-mail: [email protected]

-

4

Jessie

Phone: +86-15067393197

Landline: +86-0573-80886076

E-mail: [email protected]

-

5

Davina

Landline: +86-0573-80886076

E-mail: [email protected]

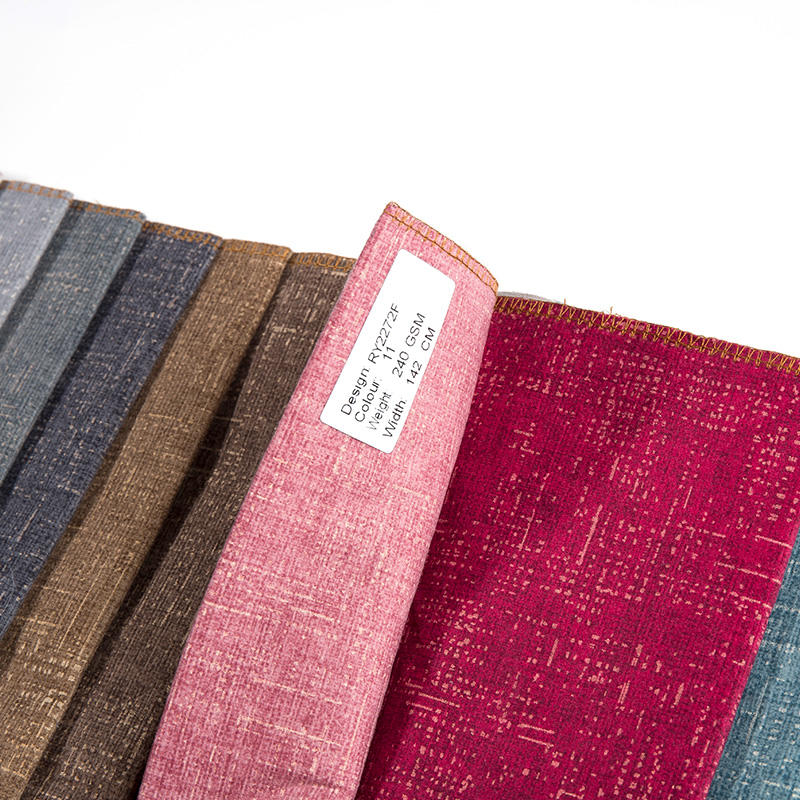

100% Polyester Sofa Bronzing Mosha velvet fabric Suppliers

The color of 100% Polyester Mosha velvet fabric can remain bright and stable for a long time, and it is not easily affected by sunlight, washing, or friction, so it has a wide range of applications, covering home decoration, car interiors, packaging materials, footwear products, and handbags and accessories. Bronzing fabrics stand out for their metallic luster and unique texture. Foil or wire is added to fabrics through the process of hot stamping, giving it a gorgeous, luxurious look.100% Polyester Sofa Bronzing Mosha velvet fabric is A high-quality, comfortable, durable, and easy-to-maintain option.

A company that manufactures and sells fabrics.

Zhejiang Royal Textile Technology Co., Ltd. is located in Tongxiang City, Jiaxing City, Zhejiang Province. 100% Polyester Sofa Bronzing Mosha velvet fabric Suppliers in China. It is an industry and trade enterprise integrating fabric production and sales. The company has imported compound machines, embossing machines, brushing machines, bronzing machines, coiling machines, and edge trimming machines, and has strong product production and finished product supply capabilities, as Custom 100% Polyester Sofa Bronzing Mosha velvet fabric Company. In addition, Royal Textile has the right to import and export independently, making the company's products exported all over the world. The company is mainly engaged in all kinds of warp-knitted fabrics, 100% Polyester Sofa Bronzing Mosha velvet fabric, and its products are mainly sold in Colombia, Brazil, Mexico, Africa, Poland, Turkey, and other parts of the world. The company has determined the development strategy of specialization, leanness, and internationalization.

Recent News

check out the latest news from indlustrios and companios.

-

17, Oct, 2024

17, Oct, 2024

How does 100% polyester velvet's texture differ from natural velvet, and why is it good for upholstery?

The texture of 100% polyester fake velvet fabric closely mimics the softness and

Read More -

10, Oct, 2024

10, Oct, 2024

How does the manufacturing process of 100% polyester Holland velvet differ from that of other velvet fabrics?

Holland velvet, known for its luxurious texture and rich appearance, stands out

Read More -

01, Oct, 2024

01, Oct, 2024

How does the pile structure of velvet sofa fabric affect its light absorption and color depth?

The pile structure of velvet sofa fabric significantly influences its light abso

Read More -

23, Sep, 2024

23, Sep, 2024

What innovations in polyester fiber technology have improved its resistance to pilling, fading?

Innovations in polyester fiber technology have significantly improved its resist

Read More

Industry Related Introduction

In the hot stamping process, pretreatment of 100% polyester sofa bronzing mosha velvet fabric is a very critical step. The main purpose of pretreatment is to ensure that the surface of the fabric is clean and smooth to improve the adhesion and overall quality of the hot stamping effect.

We need to clean the fabric first and use a soft brush or vacuum cleaner to gently remove dust and impurities on the surface of the fabric to ensure that the surface is clean and dust-free. This is because any tiny particles can cause imperfections or unevenness during the foil stamping process.

Next, check the fabric for any noticeable creases or wrinkles. If so, you need to use a steam iron or heat press to gently iron it to make the surface of the fabric smooth. A flat surface is essential for even adhesion of the foil.

For some special polyester mosaic fabrics, some specific pre-treatment may be required. For example, if the fabric has a coating or waterproofing treatment, special solvents or treatments may be needed to remove these coatings so that the foil can better adhere to the fabric.

After the pretreatment is completed, the hot stamping operation can be carried out. Please note that pre-treatment is an important part of ensuring long-lasting and beautiful hot stamping results and cannot be ignored. Therefore, before proceeding with foil stamping, be sure to carefully check the condition of the fabric and perform appropriate pre-treatment if necessary.

After discussion, it is not difficult to find that pre-treatment is a key step to ensure the perfect bronzing effect. Whether it is cleaning the surface of the fabric, ironing to remove creases, or even performing special treatments on special fabrics, every detail is related to the success or failure of the final hot stamping effect. Therefore, before performing hot stamping operations, please be sure to give sufficient attention and attention to the pre-processing process.

English

English Español

Español 中文简体

中文简体