-

1

Yolanda Wu

Phone: +86-17826810295

Landline: +86-0573-80886076

E-mail: [email protected]

-

2

Jane Shen

Phone: +86-13567361131

Landline: +86-0573-80886076

E-mail: [email protected]

-

3

Vivian Wu

Phone: +86-18358323481

Landline: +86-0573-80886076

E-mail: [email protected]

-

4

Jessie

Phone: +86-15067393197

Landline: +86-0573-80886076

E-mail: [email protected]

-

5

Davina

Landline: +86-0573-80886076

E-mail: [email protected]

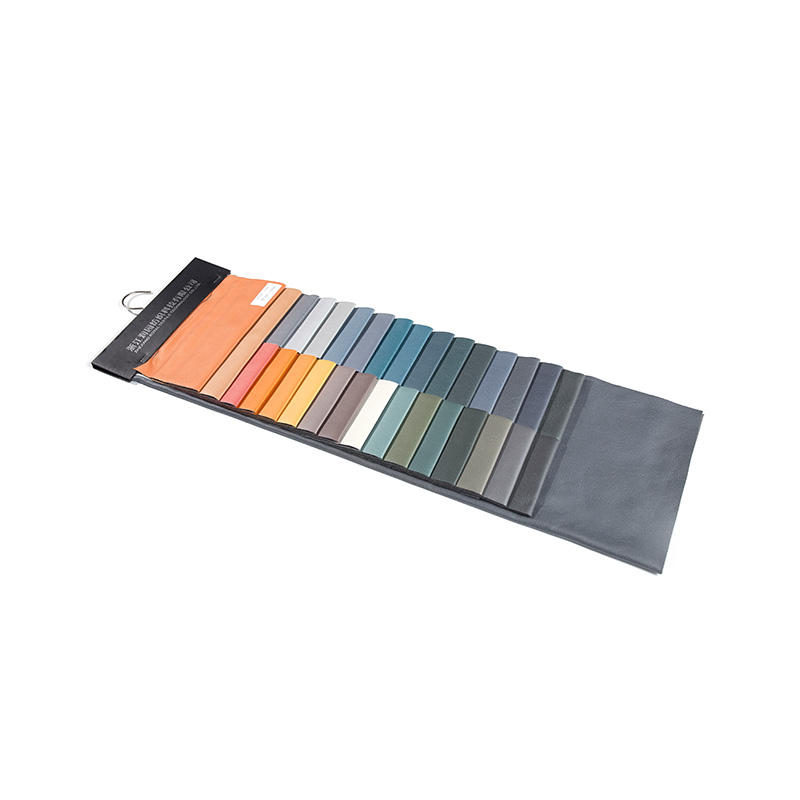

100% Polyester Sofa Bronzing+Embossed Imitation Cotton Velvet Fabric Suppliers

The 100% Polyester Sofa Bronzing++Embossed Imitation Cotton Velvet Fabric is a luxurious and versatile upholstery material that offers a host of desirable features. The embossed texture adds a tactile element to the fabric, enhancing its overall aesthetic appeal. Bronzing color can be gold, silver, two tones, and colourless. The polyester content ensures that the fabric is easy to maintain and resistant to stains, making it suitable for everyday use. The imitation cotton velvet texture is soft and plush, providing a cozy and inviting feel, making it perfect for creating a comfortable seating experience in any living space.

A company that manufactures and sells fabrics.

Zhejiang Royal Textile Technology Co., Ltd. is located in Tongxiang City, Jiaxing City, Zhejiang Province. 100% Polyester Sofa Bronzing+Embossed Imitation Cotton Velvet Fabric Suppliers in China. It is an industry and trade enterprise integrating fabric production and sales. The company has imported compound machines, embossing machines, brushing machines, bronzing machines, coiling machines, and edge trimming machines, and has strong product production and finished product supply capabilities, as Custom 100% Polyester Sofa Bronzing+Embossed Imitation Cotton Velvet Fabric Company. In addition, Royal Textile has the right to import and export independently, making the company's products exported all over the world. The company is mainly engaged in all kinds of warp-knitted fabrics, 100% Polyester Sofa Bronzing+Embossed Imitation Cotton Velvet Fabric, and its products are mainly sold in Colombia, Brazil, Mexico, Africa, Poland, Turkey, and other parts of the world. The company has determined the development strategy of specialization, leanness, and internationalization.

Recent News

check out the latest news from indlustrios and companios.

-

23, Jul, 2024

23, Jul, 2024

What are the chemical compositions and fiber structures of velvet sofa fabrics?

Velvet sofa fabrics typically consist of fibers like cotton, silk, or synthetic

Read More -

18, Jul, 2024

18, Jul, 2024

How well does sofa upholstery fabric return to its original shape after being stretched?

To evaluate how well sofa upholstery fabric returns to its original shape after

Read More -

11, Jul, 2024

11, Jul, 2024

What are the thermal and moisture-wicking properties of polyester couch fabric?

Polyester couch fabric has specific thermal and moisture-wicking properties that

Read More -

04, Jul, 2024

04, Jul, 2024

What are the current market trends in the polyester couch fabric industry?

The polyester couch fabric industry is influenced by several market trends drive

Read More

Industry Related Introduction

Hot stamping and embossed lint-like fabrics, especially 100% polyester sofa bronzing embossed imitation cotton velvet fabrics, require certain requirements when sewing. This fabric not only has the toughness of polyester, but also combines the soft touch and good warmth of cotton-like velvet. At the same time, the hot stamping and embossing process gives the fabric a unique decorative effect, requiring the stitching process to be more delicate and sophisticated.

Since foil stamped velvet-like fabrics usually have a thicker texture and decorative layer, choose the right sewing needle. The needle tip needs to be able to penetrate the fabric stably and smoothly to avoid damaging the decorative layer of the fabric or causing skipped stitches during the sewing process. At the same time, the size of the needle eye should also match the thickness of the suture to ensure that the stitches are firm and beautiful.

In terms of sutures, considering the wear resistance and strength of polyester, polyester threads or high-strength synthetic fiber threads that match the fabric should be used for sutures. This not only ensures the firmness of the stitches, but also maintains the overall coordination and beauty of the fabric.

During the sewing process, because the hot stamping and embossed imitation velvet fabric has a special decorative effect, uneven or rough stitches may destroy the overall beauty. Therefore, when sewing, you need to pay attention to controlling the stitch length and the tightness of the stitches to keep the stitches clear and beautiful.

In order to prolong the use time, elastic sutures and appropriate stitching methods need to be used when sewing the sofa fabric so that the sofa can maintain its shape and beauty during long-term use. At the same time, in order to enhance the wear resistance of the fabric, reinforcement measures can be added during the sewing process, such as increasing the sewing density or using other sewing techniques.

English

English Español

Español 中文简体

中文简体